Vicor Robotics Application Products

Almost everything around humans is touched at some point by robots. Robotic applications are utilized in agricultural harvesting, warehouse inventory movement, campus delivery, and consumer delivery. These robots are fueled by batteries, making power conversion efficiency and size/weight critical. Power conversion needs become more and more challenging as load capacity, visual recognition, and user functionality requirements increase within the robotic application.Vicor power modules support a component-based power delivery network to power motor drives and demanding CPUs. Each power module is optimized for high efficiency, density, and overall performance. Vicor modules are also lightweight compared to competitive solutions, enabling further performance gains for battery-powered robotic devices. Power modules can also be paralleled, allowing designs to easily scale in power as robotic power demands increase and allowing the same power architecture to be deployed within a platform of various-sized robot systems.

Videos

Applications

Robots that Harvest

Produce such as strawberries, apples, and lettuce are planted, maintained, and harvested using automated vehicle guidance and visual recognition robotics. Large robotic vehicles or equipment are typically powered from a high-voltage DC source of 400V or more.

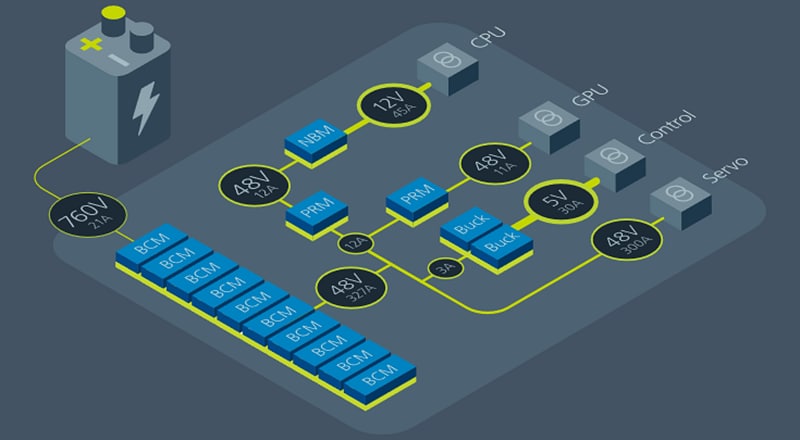

Harvesting Robots

In this type of design, the Vicor BCM converter series can provide high-voltage battery conversion to a safe, nominal 48V. One example is the BCM4414, which is capable of more than 1,600W at greater than 97% efficiency from its 111mm x 36mm x 9mm package. The BCM is a fixed ratio converter with an output of 1/16 of the input voltage. Fixed ratio or regulated point-of-load converters such as Vicor NBMs, PRMs, ZVS Buck, and ZVS Buck-Boost regulators power individual, downstream, and lower-voltage rails as needed.

Robots that Deliver

These robots' mission-critical tasks are last-mile consumer delivery of groceries, take-out food, and online consumer items. While payloads vary in size and weight, these robots typically have longer run times than the moving class and are typically powered by 48V to 100V batteries.

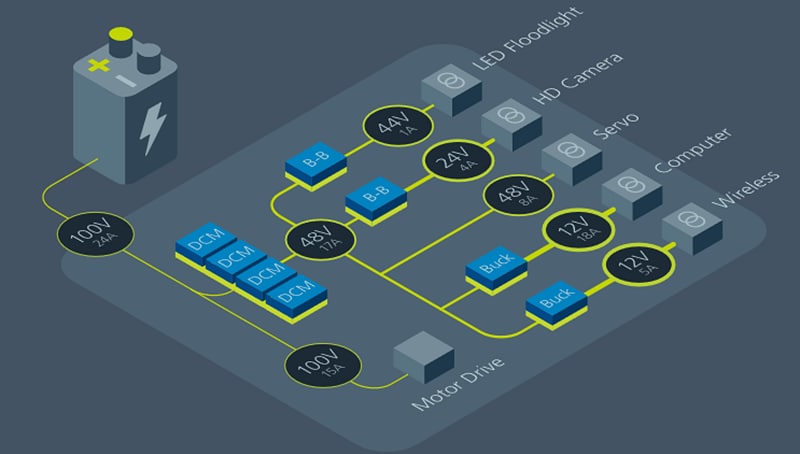

Delivery Robots

The DCM converter series fits the needs of this class, operating from 43V to 154V input. The DCM3623 enables regulated 24V or 48V distribution from the battery for servo drives, other payloads, and downstream converters. It provides 240W of power at 90% efficiency from a 36mm x 23mm x 7.3mm package. With a 24V to 48V rail established, ZVS Buck or Buck-Boost regulators can typically be used to power lower-voltage rails.

Robots that Move

These nimble robots manage inventory and order fulfillment within large warehouse environments. This robot class is typically powered from a 24V to 72V battery source, with charging performed as needed. With high efficiency and small footprints, Vicor power modules support conversion from up to 75V to usable voltages within the robot to efficiently power all mobility, guidance, computing, radio, and lighting functions.

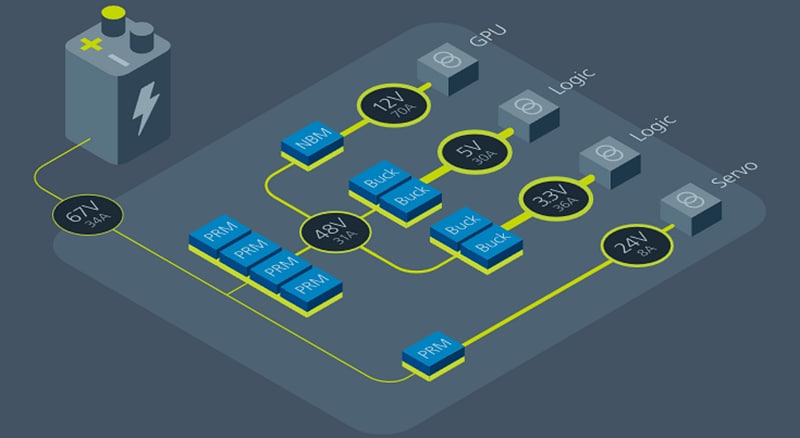

Robots Using a 67V Battery

The first powertrain architecture highlights the PRM power module, a high-performance buck-boost regulator. The PRM creates an intermediate bus of 24V to 48V with 96% to 98% efficiency to power servos and additional downstream power modules, including fixed ratio NBMs, ZVS Buck, and ZVS Buck-Boost regulators. All modules can also be paralleled for higher power conversion.

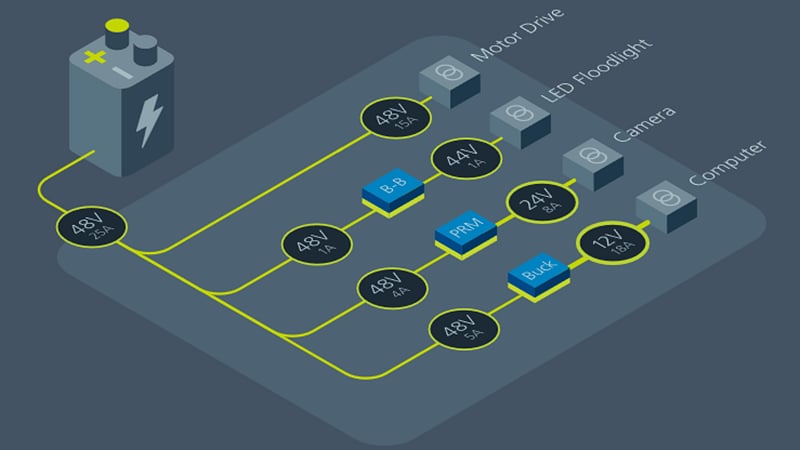

Robots Using a 24V to 48V Battery

The second powertrain architecture highlights direct conversion from the battery to the point-of-load. PRM, ZVS Buck, and ZVS Buck-Boost regulators support these applications. One example is the PI3740 ZVS Buck-Boost regulator, which provides more than 100W of power from a 10mm x 14mm x 2.5mm SiP package with up to 96% peak efficiencies.